Introduction

This chapter presents an introduction to the history of flying balloons, the physics of balloon flight, balloon components, balloon terminology, support equipment, and how to choose a balloon.

History

Hot air balloons are the oldest successful human flight technology. The first recorded manned balloon flight was made on November 21, 1783 in a hot air balloon developed by the Montgolfier brothers of France. [Figure 2-1] Flown by Pilatre de Rozier and the Marquis d’Arlandes, the flight lasted 23 minutes and covered 5.5 miles. Although the Montgolfiers are given credit for the first documented flight, there are some earlier claims. The Chinese are credited with using manned kites, and perhaps hot air balloons, some 2,000 years ago, and the Nazcas of Peru may have used smoke-filled balloons.

Figure 2-1. Model of the Montgolfier brothers balloon.

Ten days after the successful flight of the Montgolfier balloon, a young physicist, Professor Jacques Charles flew the first gas balloon made of a varnished silk envelope filled with hydrogen. His flight lasted two hours and covered 27 miles, reaching an altitude of 9,000 feet. Begun as an attempt to duplicate and validate the achievements of the Montgolfier brothers, Charles based his experiment on misinformation. He mistakenly believed the Montgolfier brothers used hydrogen to inflate their balloon, so he used hydrogen. Thus, the two kinds of balloons flown today—hot air and gas—were developed in the same year.

Gas ballooning became a sport for the affluent and flourished on a small scale in Europe and the United States. Since ballooning drew crowds, one way to offset the cost of a flight was to charge admission. Ballooning was a perilous undertaking that drew male and female daredevils eager to court danger. The parachute, invented by balloonist Andre Garnerin in 1797 as the means of performing a daring stunt, is probably ballooning’s most significant contribution to flight.

At the turn of the century, the smoke balloon (a canvas envelope heated by fire on the ground) was a common county fair opening event. As the smoke balloon ascended, a man or woman rider balanced on a trapeze attached to the balloon.

After the initial climb (about 3,000 feet per minute (fpm)) the hot air cooled and the rider separated from the balloon, deploying a parachute to return to earth.

Balloons also found a home with the military. Napoleon used anchored observation balloons in some of his battles and considered using balloons to ferry troops in his proposed invasion of England. During the American Civil War, both the North and South used tethered observation balloons. In Europe, balloons were used during the 1870 siege of Paris (Franco-Prussian War) to carry messages and important people out of Paris. World War I saw balloons used by both sides for artillery spotting. By World War II, airplanes had replaced balloons for observation and reconnaissance purposes although barrage balloons (several large balloons tethered close together were often used to discourage low level bombers or dive bombers. The United States Navy contracted with the General Mills Company in the 1950s to develop a small hot air balloon for military purposes. The Navy never used the balloon, but the project created the basis for the modern hot air balloon. With the use of modern materials and technology, hot air ballooning has become an increasingly popular sport.

Physics

In concept, the balloon is the simplest of all flying machines.

It consists of a fabric envelope filled with a gas that is lighter than the surrounding atmosphere. Since air in the envelope is less dense than its surroundings, it rises, taking the basket filled with passengers or payload with it. A balloon is distinct from other aircraft in that it travels by moving with the wind and cannot be propelled through the air in a controlled manner.

There are two main types of balloons, hot air and gas, but other specialty type balloons are also flown. The Rozier balloon is an example of a less common balloon. A hybrid balloon that utilizes both heated and unheated lifting gases for long distance record flights, a Rozier was flown by Steve Fossett in his record-setting first solo circumnavigation in

2002. A recent addition to the hot air balloon field is the solar balloon, which uses heat radiation from the sun to provide lift. This handbook primarily covers hot air balloons.

Why Do Balloons Fly?

The physics of balloon flight is based on the principles of fluid dynamics and associated theorems. Therefore, it is helpful to think of the air, the medium of balloon flight, as a fluid when discussing the concept of “buoyancy” as applied to balloon flight. In physics, buoyancy is the upward force of an object produced by the surrounding fluid (i.e., liquid or gas) in which it is fully or partially immersed, due to the pressure difference of the fluid between the top and bottom.

Figure 2-2. The air inside the balloon envelope is heated to create buoyancy.

of the object. The net upward buoyancy force is equal to the magnitude of the weight of fluid displaced by the object. This force enables the object to float or at least to appear lighter.

An object must make room for its own volume by pushing aside, or displacing, an equal volume of liquid. For example, an aircraft carrier exerts downward force on the water and the water exerts upward force on the aircraft carrier. A solid object floats when it has displaced just enough water, or air in the case of a balloon, to equal its own original weight.

To create the necessary buoyancy for flight, the air inside the balloon envelope is heated which causes the air to expand, making it less dense. [Figure 2-2] Once the interior air weighs less than the non-heated ambient air (air that surrounds an object), the balloon becomes lighter in weight and rises in an effort to find a level where the interior air density matches that of the exterior air density. The envelope is carried along

“for the ride,” as it does little more than contain the heated air mass. The balloon rises to a point where the lift created by the action of heating the air is equal or greater than that of the balloon itself. The balloon rises because it has reached a state of “positive buoyancy” and the amount of lift is greater than the weight of the balloon.

The greater the heat differential between the air inside the envelope and the ambient air, the faster the balloon rises. Hot air is constantly being lost from the top of the envelope by leaking through the fabric, seams, and deflation port. Heat is also lost by radiation. Only the best and newest fabrics are nearly airtight. Some fabrics become increasingly porous with age and some colors radiate heat faster than others do. Under certain conditions, some dark colored envelopes may gain heat from the sun. To compensate for heat loss, prolonged flight is possible only if fuel is carried on board to make heat.

The internal temperature of the air in the envelope is raised or lowered to change altitude. To climb, the temperature in the envelope is raised by heating the air which creates more lift. To descend, the air in the envelope is allowed to cool.

Cooling of the envelope is also possible by allowing hot air to escape through a vent. This temporary opening closes and seals automatically, due to the upward pressure, when it is not in use.

A balloon’s weight when in flight is not only the figure as stated in the flight manual, but also includes the weight of the air within the inflated envelope, the balloon components and equipment, as well as the pilot and passengers. The average 77,000 cubic foot hot air balloon contains an air mass that weighs over 3,000 pounds. By adding all these factors together, it is easy to understand how weight influences the balloon’s response to pilot actions during flight maneuvers.

The weight and sheer momentum of a balloon in flight make it difficult for a pilot to effect rapid changes.

Balloon Components

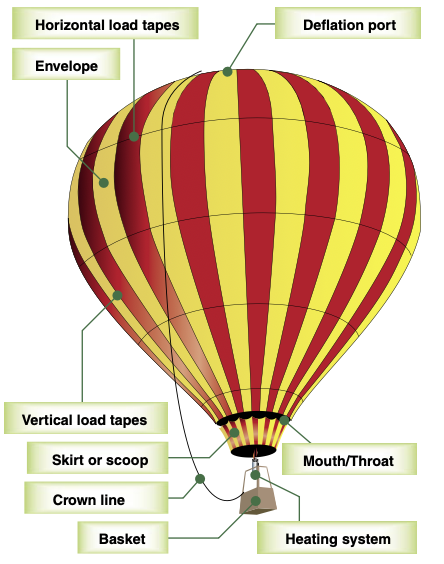

A hot air balloon consists of three main components: envelope, heater system, and basket. In addition, flight instruments, fuel tanks, and other support equipment are needed for a safe balloon flight. (Figure 2-3] The most common ballooning terms are used in the following text, in

Figure 2-3. Basic balloon terms.

the generic illustrations, and are also listed in the glossary which contains balloon and aeronautical terminology. Some terms and names used by manufacturers are also included.

Envelope

The envelope is usually made of light-weight and strong synthetic fabrics such as ripstop nylon or Dacron®. The material is cut into panels which are sewn together in vertical rows that are called gores due to their triangular shape.

The traditional envelope shape is a teardrop. The gores are reinforced with sewn-in webbing called horizontal and vertical structural load tapes which are continuous to the top center of the balloon where they are sewn into a load ring. Galvanized, stainless steel, or Kevlar® cables transfer basket loads to load tapes which in turn support the load.

The nylon “skirt” at the base of the envelope is coated with special fire resistant material to keep the flame from igniting the balloon.

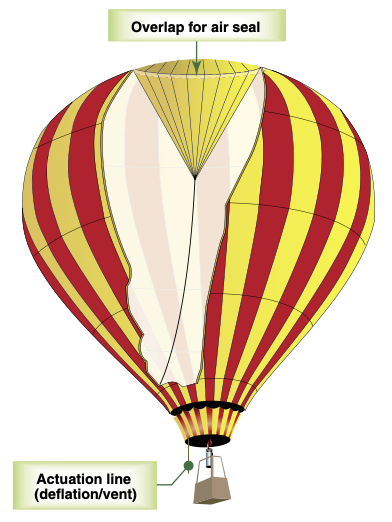

The deflation port is located at the top of the envelope and allows for the controlled release of hot air. It is covered by the deflation panel sometimes called a top cap, parachute top, or spring top. [Figure 2-4] In a balloon with a parachute top, partial opening of the parachute valve is the normal way to cool the balloon. Balloons with other types of deflation panels may have a cooling vent in the side or the top. Many balloons are also equipped with turning vents, which allow for the pilot to turn the balloon on its vertical axis while in

Figure 2-4. Deflation system.

flight. Turning vents help a pilot align the basket for landing, or in the case of commercial balloons, align the balloon’s logo toward the crowd.

Special Shape Balloons

Balloons that do not have a traditional “teardrop” shape are called special shape balloons. [Figure 2-5/ They may be completely engineered systems which have been designed to resemble cans, sports balls, cartoon characters, cars, etc.

Figure 2-5. Special shape balloons.

Some balloons have appendages added to the envelope.

Appendages are pieces added to a balloon envelope in order to create a particular shape or rendition, not necessarily keeping with a standard shape balloon. To be designated an appendaged envelope, less than 10 percent of the total capacity of the balloon is contained within the appendage.

While the appendaged envelope has the same general flight characteristics as a standard balloon shape, there are some differences. For example, the added weight of the appendage may cause the overall envelope to weigh significantly more than teardrop balloons of equal size. Appendage balloons also have the tendency to rotate during aggressive climbs and descents.

A special shape envelope requires a substantial amount of engineering to ensure the envelope is properly stressed, and the balloon has no undesirable flight characteristics due to the shape. Special shape balloons built in the United States or the United Kingdom are normally issued Standard Airworthiness Certificates, but special shape balloons imported from other manufacturers in other countries may be issued an Experimental Airworthiness Certificate. A balloon with an Experimental Airworthiness Certificate usually may not be flown for compensation or hire, which negates the marketability of such a balloon. Additionally, an experimental balloon may not be flown over congested areas per Title 14 of the Code of Federal Regulations (14 CFR) part 91, section 91.319. Experimental balloons also require specific documentation when flown outside of an area of 50 miles from its home port. Pilots of special shape balloons with an Experimental Airworthiness Certificate should coordinate their activities with their local Flight Service District Office to avoid problems.

Thermal Airships

A thermal airship combines the characteristics of a hot air balloon, with respect to lifting force, and an airship, with respect to its capacity of being steered while in flight. To develop proficioney in this aircraft, knowledge is required of not only hot air balloon operations and physics, but also of airship operations. It is estimated that there are currently less than 10 of these aircraft in the United States, and there is no specific pilot certificate for thermal airships. These aircraft are extremely expensive to purchase, and have some significant operating limitations with reference to winds. Any further discussion is outside the scope of this handbook.

Heater System

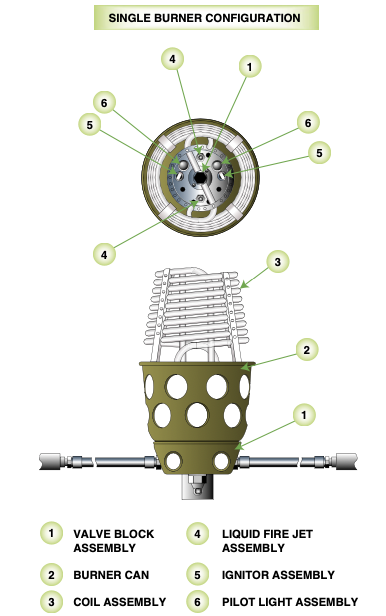

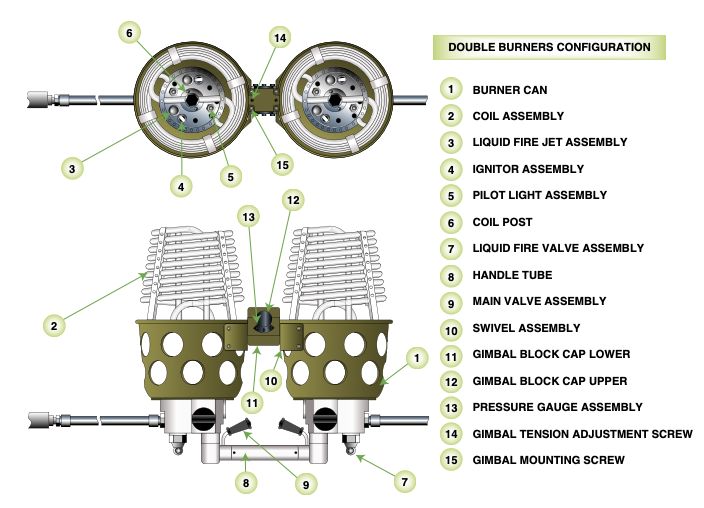

The heater system consists of propane burners (one or more), fuel tanks that store liquid propane, and fuel lines that carry the propane from the tanks to the burners. The burners convert ambient air into hot air, which in turn provides the lift required for flight. (Figures 2-6 and 2-7)

Figure 2-6. Typical single heater (burner).

Figure 2-7. Typical double heater (burner).

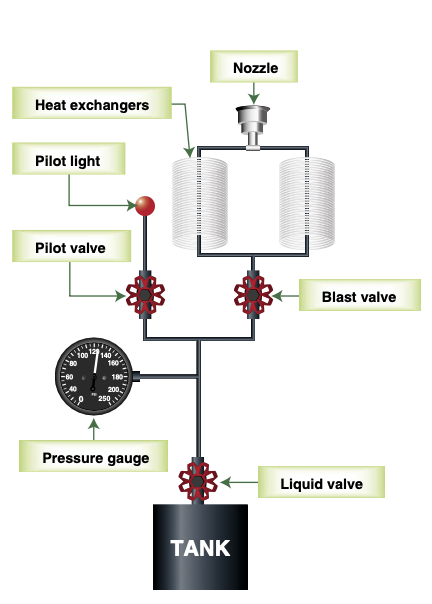

Propane fuel is used to heat the air which generates buoyancy for flight. The propane is stored in one or more fuel tanks located in the basket. A withdrawal tube attached to the liquid tank valve permits liquid propane to be drawn from the bottom of the fuel tanks. The liquid propane is supplied to the burner assembly through the fuel hoses that connect the fuel tanks to the heater assembly (commonly referred to as the burner). The fuel system also provides propane to the pilot light.

There are two types of pilot light systems: liquid and vapor.

In a liquid pilot light system, liquid propane is diverted from the main supply line at the heater via a pilot shut-off valve.

The fuel goes through a vapor converter and regulator, and is distributed through a pilot head. A piezo-electric system ignites the vapor at inflation for most heaters, but many balloonists choose to use a striker.

In a vapor pilot light, a second fuel hose is used to supply vapor to the heater assembly pilot light from the pilot light tank valve located on top of the fuel tank. A regulator is used to decrease the pressure of the propane vapor for proper pilot operation. A pilot light valve located on the heater controls the flow of propane vapor to the pilot light.

The main liquid tank valve controls the flow of liquid propane to the burner, while the blast valve controls fuel flow at the heater. With the liquid tank valve open, opening the burner blast permits liquid propane to enter the heat exchange coil where it is either completely or partially vaporized. After exiting the heat exchange coil through the orifices in the lower portion of the coil, the propane is ignited by the pilot light. (Figure 2-8]

To meet redundancy requirements, heaters have a secondary system which allows for operation at a reduced efficiency should a problem develop with the main blast valve. These backup, or bypass systems generally have proprietary names unique to the individual manufacturers. Pilots should consult individual flight manuals for an explanation of their use.

The heaters typically have an output of approximately 20 million British thermal units (BTU) in use. There is a power loss associated with altitude, generally considered to be four percent per thousand feet of altitude. This is particularly important when dealing with higher density altitudes.

Pilots accustomed to flying at lower altitudes are frequently surprised by the decreased performance of their balloon upon their first flight at a higher altitude.

Basket

Wicker is the preferred material for the passenger compartment basket of a hot air balloon because it is sturdy, flexible, and relatively lightweight. /Figure 2-9/ The flexibility of wicker

Figure 2-8. Fuel system schematic.

Figure 2-9. Representative sport basket configuration.

helps with balloon landings and cushions some of the impact force at landing. The basket contains the fuel tanks, instruments, pilot, and passengers.

Aluminum, stainless steel, or flexible nylon poles (in conjunction with stainless steel cables) located on the upper portion of the structure transfer the basket load to the envelope attachment points and support the burner assembly. Quick pins or aircraft bolts connect the support tubes, with nylon rods usually inserted into the sockets, and the cables attached around them. Lower frame tubes support the floor, permitting the floor load to be transferred to the lower frames. Oak skids, usually affixed to the floor, add rigidity and provide a point of abrasive resistance to the floor. Rattan sidewalls of varying thickness, design, and color surround and protect the passengers, equipment, and fuel tanks. Larger baskets, usually found on large ride balloons, may have padded basket dividers to form passenger compartments.

Instruments

As required by 14 CFR part 31, balloons are equipped with an altimeter, a rate of climb indicator, fuel quantity gauges, and an envelope temperature gauge. Many newer balloons use some type of electronic instrument system, but older balloons may still be equipped with traditional, pressure driven analog instruments.

The most common arrangement of instruments is a small pod or package which includes the altimeter, rate of climb indicator (variometer or vertical speed indicator), and the envelope temperature gauge (pyrometer). A cable is plugged into the instrument package during the preflight or layout process which connects to a sensor located in the top of the balloon and operates the envelope temperature gauge. Fuel quantity gauges, located on the top portion of each fuel tank, provide a reference for the quantity of fuel remaining in the tank. As these gauges are mechanical, they are sometimes inaccurate, and in most configurations do not read from 0 to 100 percent. This needs to be taken into consideration during the flight planning process.

In recent years, many manufacturers have added a wireless system that transmits the temperature signal to a receiver in the basket via a radio or infrared signal. This eliminates the necessity of a wire being located in the balloon envelope.

These instrument systems are popular, but have reliability issues because radio interference or the thermal “plume” from the burner can degrade the signal transmission.

Fuel Tanks

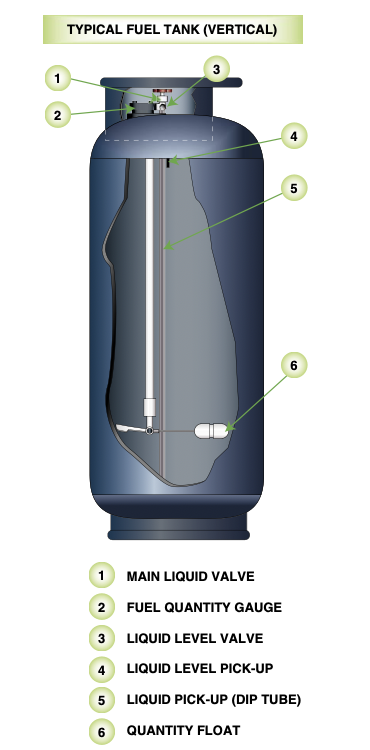

Balloons generate heat through the use of propane. The propane is contained in aluminum or stainless steel tanks mounted inside the basket. These tanks may be either vertical or horizontal, and contain 10, 15, or 18 gallons of propane. Larger tanks are available for larger ride balloons.

(Figure 2-10]

The tanks, sometimes referred to as pressure vessels, are commonly equipped with a service valve (or main liquid valve), a fixed maximum liquid level gauge (or “spit valve”), a float gauge, and a pressure relief valve. The service valve regulates the flow of the liquid propane to the heater. The fixed maximum liquid level gauge provides an indication that the tank is filled to its maximum design quantity, or 80 percent of the total capacity of the tank. The float gauge provides a reading of the remaining capacity of the tank in a percentage.

The pressure relief valve allows for the release of propane from the tank should the tank exceed the maximum design pressure. A pressure relief valve normally releases at 375 pounds per square inch (psi). Figure 2-11 provides additional information on propane management.

Figure 2-10. Typical fuel tank.

Figure 2-11. Propane primer. (Propane pressures at different temperatures are listed in Appendix A.)

Support Equipment

Standard support equipment for ballooning includes an inflation fan, transport/chase vehicle, and small miscellaneous items, such as igniters, drop lines, gloves, spare parts, and helmets.

Inflation Fans

The inflation fan is one of the most dangerous pieces of equipment in ballooning. [Figure 2-12/ Keep this fact in mind when purchasing and operating any inflation fan. Fan blades have been known to shatter or break, throw rocks at high velocity, and inadequate cages or guards fail to protect fingers and hands. Any fan considered for purchase by a prospective pilot should be evaluated for potential safety hazards. Also, remember that the blade spinning at high revolutions per minute (rpm) generates a significant gyroscopic effect. Fans should not be moved while running. If the fan must be moved, it should be shut off, repositioned, and restarted.

Fans come in different styles and sizes. Personal finances, style of inflation, and size of the balloon determines the best fan. Points to consider in selecting a fan are:

- Weight-someone has to lift the fan into and out of the transport vehicle. Wheels help one person move the fan, but they add to the weight and are not helpful on soft ground. One person can carry a small fan, but a larger fan may require two people.

- Safety—fan blades today can be wood, aluminum, fiberglass, or composite, with wood being the most popular. Wood or aluminum blades designed specifically for balloon fan use are best. The fan should

Figure 2-12. Balloon inflation using a typical inflation fan.

have a cowling of fiberglass or metal because a cage or grill alone is not sufficient to stop rocks or pieces of blade from being thrown.

• Transport-available space in a pickup truck, the back of a van, or on a trailer may determine the size of the fan.

Cubic feet per minute (CFM)—fan blade design, duct design, and engine speed determine the amount of air moved in a given time. Do not confuse engine size with CFM. Larger engines do not necessarily push more air. The volume of air moved is primarily a function of blade design and performance. Moving a high volume of air is not necessarily the ultimate goal in fan performance. Some people prefer a slower cold inflation to accommodate a thorough preflight inspection.

Fuel-gasoline degrades in storage. Do not store gasoline in the fan due to fire hazard and the formation of varnish, which can clog fuel passages.

• Fan maintenance— a good fan requires little maintenance and should be easy to maintain. Check the oil periodically and change it once a year. Check hub bolts and grill screws for tightness on a regular basis.

Transport/Chase Vehicle

Balloon ground transportation varies. [Figure 2-13/ The most common vehicles are a van with the balloon carried inside, a pickup truck with the balloon carried in the bed, or a van or pickup truck with a small trailer (flatbed or covered). Some considerations in selecting a transport/chase vehicle are:

- Finances—if costs are an issue, a trailer hitch on the family sedan and a small flatbed trailer may work just fine.

- Convenience-for ease of handling the balloon, a small flatbed trailer low to the ground makes the least lifting demands on the pilot and crew. One consideration is that volunteer crew members may have little or no experience in backing a small trailer.

Number of crew members—if the number of crew members is small, handling the balloon should be made as easy as possible. If the number of crew members is large, the size of the chase vehicle and other factors may be more important. - Storage—some balloonists, who do not have room for inside storage and want security on the road, choose an enclosed trailer. If an enclosed trailer is used for storage of the balloon, the trailer should be a light color to help reduce the heat inside. Keeping the trailer cool keeps the tank pressure within reasonable limits (so as not to aggravate a potential fuel leak), and reduces the vaporization of gasoline in the fan tank (the fumes

Figure 2-13. This is an example of a transport vehicle which carries a small balloon, three adults, a 20-inch inflation fan, and all other necessary equipment.

can attack the composition of the balloon’s fabric and render it unairworthy).

• Vehicle suitability-terrain, vehicle road clearance, and number of chase crew members are factors that determine the suitability of a transport/chase vehicle.

Quick/Safety Release

Safety restraints, referred to as “quick releases” or “safety tie downs,” are used in balloon inflations. They are designed to restrain the balloon from movement in breezy or windy conditions.

There are several different types of safety restraints available, but none are part of the aircraft certification process. This lack of aircraft certification has led to controversy over the use of safety restraints among ballooning enthusiasts. Since event participation often requires their use for safety reasons, the use of safety restraints is now recommended for balloon launches. Each type of restraint has its own advantages and disadvantages which a pilot can learn via observation and discussion with an instructor and/or other balloon pilots.

When a pilot decides to utilize a safety restraint, it is important to follow the balloon manufacturer’s recommendations on how to attach it to the balloon superstructure. Many balloons have been seriously damaged by using an improperly attached restraint in excessive winds.

It is also important to insure that all personnel involved with the inflation, whether pilot, crew or spectator, be aware of the dangers of a safety restraint. The quick release rates with the inflation fans as one of the most hazardous pieces of equipment on the launch field. Early release under load, or breaking of the safety restraint may cause serious injury. All personnel involved should be briefed and made aware of the potential hazards.

Miscellaneous Items

- Radios—most pilots use some kind of two-way radio for air to ground communication. There are many choices available, ranging from Family Radio Service (FRS) and General Mobile Radio Service (GMRS) radios, which are relatively low cost, to the more sophisticated FM business band systems, which can be expensive.

The GMRS and FM radios require licensing by the Federal Communications Commission (FCC).

FRS radios do not. Using cell phones for air-ground communications is a violation of FCC rules. - Igniters-most manufacturers provide at least two sources of ignition on board. The best igniter is the simple welding striker. Nearly all balloons have built-in piezo ignition systems.

Fueling adapter-adapters are required to connect the balloon fuel tanks to the propane source. Pilots should carry their own adapters to ensure the adapters are clean and not worn. Dirty and worn adapters may damage a fuel system. - Compass—compasses are used to track pibals, check map orientations, and navigate the balloon. While almost any good quality compass will do, the best kind to use is probably the sighting compass.

- Fire extinguisher—most balloons now come equipped with small fire extinguishers affixed to the basket. If one is present, it will be inspected during the annual inspection. These fire extinguishers are often too small to extinguish grass fires or serious basket fires caused by a propane leak. In the case of a propane-leak fire, turning off a valve usually extinguishes the fire. This is a better use of pilot time than fumbling for a fire extinguisher that might not extinguish the fire.

- First aid kit the location and contents of first aid kits vary. Some pilots keep a small first aid kit in their balloon; some keep one in the chase vehicle. A frequent topic at Safety Seminars, the contents of the kit often depend on the area of the country in which the balloon is flown.

- Drop line-drop lines allow ground crew to assist the pilot in landing in a confined area, or to move the balloon to an area better suited for deflation and retrieving. A good drop line has a quick release provision; is easy to deploy, recover and store; and is easy for a person on the ground to handle. Webbing is a popular drop line material because it is strong. Webbing is hard to roll up, but easy to store. Half-inch nylon braid is strong and is easily rolled into a ball and put in a bag.

- Gloves—pilots and crew members should develop the habit of wearing gloves anytime they handle the balloon and associated equipment. A well fitting pair of gloves can reduce the injuries that occur while handling balloon equipment, such as rope, cables, bag handles, etc. In the case of a small fuel leak at a burner fitting, gloves can minimize a potentially disastrous situation.

- Gloves should be made of light colored smooth leather to reflect/deflect propane, and gauntlet style to cover the wrist. Avoid synthetic material which melts in heat and ventilated gloves which let in flame or gas.

A second pair of gloves, of appropriate rubberized material and looser fit, can be used to conduct refueling operations.

Helmets-balloon manufacturers usually mandate protective headgear be worn, especially in high wind conditions to protect heads from impact injury. Store helmets in a bag that can be carried inside or outside the basket, depending on number of passengers and available room.

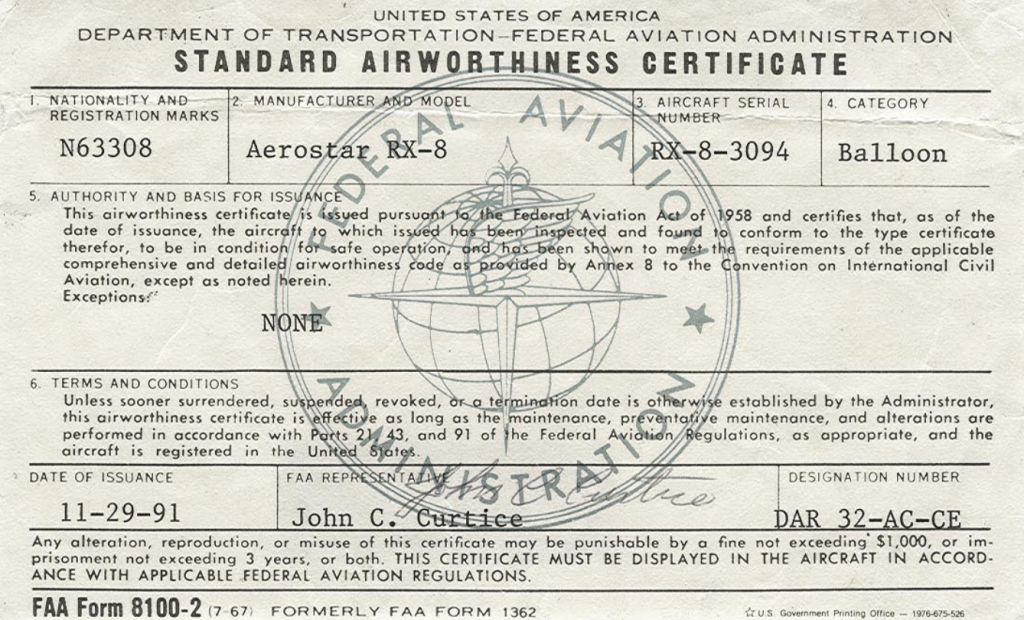

Figure 2-14. Standard Airworthiness Certificate.

• Spares-the following are recommended spares to carry in the chase vehicle or to have on hand:

- Local and aeronautical maps

- Helium tank and pibals (pilot balloons)

- Quick pins and carabiners

- Gloves and helmets

- Envelope fabric and/or patches

- Refueling adapters

- Spare tire for the trailer

- Extra fuel for the fan

- Extra strikers/igniters

Aircraft Documents

Airworthiness Certificate

An Airworthiness Certificate is issued by a representative of the FAA after the balloon has been inspected, is found to meet the requirements of 14 CFR part 31, and is in condition for safe operation. The Airworthiness Certificate must be displayed in the aircraft so it is legible to the passengers and crew whenever it is operated. [Figure 2-14] The Airworthiness Certificate is transferred with the aircraft except when it is sold to a foreign purchaser.

A Standard Airworthiness Certificate is issued for aircraft type certificated in the normal category for manned free balloons. A Standard Airworthiness Certificate remains in effect as long as the aircraft receives the required maintenance and is properly registered in the United States. Flight safety relies, in part, on the condition of the aircraft, which is determined by inspections performed by mechanics, approved repair stations, or manufacturers who meet specific requirements. A Special Airworthiness Certificate is issued for all aircraft certificated in other than the Standard classifications, such as Experimental or Restricted. When purchasing an aircraft classified as other than Standard, it is recommended that the local FAA Flight Standards District Office (FSDO) be contacted for an explanation of the pertinent airworthiness requirements and the limitations of such a certificate.

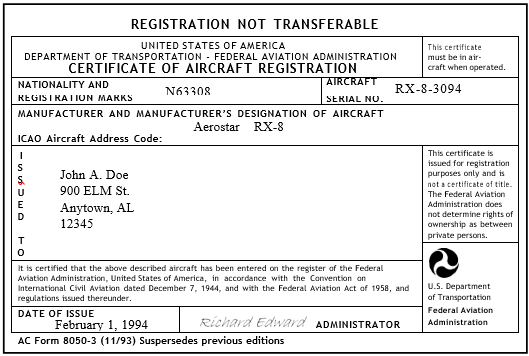

Certificate of Aircraft Registration

Before an aircraft can be flown legally, it must be registered with the FAA Civil Aviation Registry. The Certificate of Aircraft Registration, which is issued to the owner as evidence of the registration, must be carried in the aircraft at all times. [Figure 2-15] The Certificate of Aircraft Registration cannot be used for operations when:

- The aircraft is registered under the laws of a foreign country.

- The aircraft’s registration is canceled at the written request of the holder of the certificate.

- The aircraft is totally destroyed or scrapped.

- The ownership of the aircraft is transferred.

- The holder of the certificate loses United States citizenship.

Figure 2-15. Certificate of Aircraft Registration

When one of the events listed in 14 CFR part 47, section

47.41 occurs, the previous owner must notify the FAA by filling in the back of the Certificate of Aircraft Registration, and mailing it to:

Federal Aviation Administration Civil Aviation Registry, AFS-750

P.O. Box 25504

Oklahoma City, OK 73125

After compliance with 14 CFR part 47, section 47.41, the pink copy of the application for a Certificate of Aircraft Registration is authorization to operate an unregistered aircraft for a period not to exceed 90 days. Since the aircraft is unregistered, it cannot be operated outside the United States until a permanent Certificate of Aircraft Registration is received and placed in the aircraft.

NOTE: For additional information concerning the Aircraft Registration Application or the Aircraft Bill of Sale, contact the nearest FSDO.

Aircraft Owner/Operator Responsibilities

The registered owner/operator of an aircraft is responsible for certain items, such as:

- Having a current Airworthiness Certificate and a Certificate of Aircraft Registration in the aircraft.

- Maintaining the aircraft in an airworthy condition, including compliance with all applicable Airworthiness Directives.

- Assuring that maintenance is properly recorded.

- Keeping abreast of current regulations concerning the operation and maintenance of the aircraft.

Aircraft Maintenance

Maintenance is defined as the preservation, inspection, overhaul, and repair of an aircraft, including the replacement of parts. A properly maintained aircraft is a safe aircraft. In addition, regular and proper maintenance ensures that an aircraft meets an acceptable standard of airworthiness throughout its operational life. Although maintenance requirements vary for different types of aircraft, experience shows that aircraft need some type of preventive maintenance every 25 hours of flying time or less, and minor maintenance at least every 100 hours. This is influenced by the kind of operation, climatic conditions, storage facilities, age, and construction of the aircraft. Manufacturers provide maintenance manuals, parts catalogs, and other service information that should be used in maintaining the aircraft.

Balloon Inspections

14 CFR part 91 places primary responsibility on the owner or operator for maintaining a balloon in an airworthy condition. Certain inspections must be performed on the balloon, and the owner must maintain the airworthiness of the balloon during the time between required inspections by having any defects corrected. This typically means that fabric damage outside the maximum allowable damage limits specified by the manufacturer must be repaired before the envelope can be deemed airworthy and returned to service.

Annual Inspection

Any balloon flown for business or pleasure and not flown for compensation or hire is required to be inspected at least annually. The inspection must be performed by a certificated and appropriately rated repair station, by the manufacturer, or by a certificated airframe and powerplant (A&P) mechanic who holds an Inspection Authorization (IA). The aircraft may not be operated unless the annual inspection has been performed within the preceding 12 calendar months. A period of 12 calendar months extends from any day of a month to the last day of the same month the following year.

100- Hour Inspection

All balloons used to carry passengers for hire must have received a 100-hour inspection within the preceding 100 hours of time in service and have been approved for return to service. Additionally, an aircraft used for flight instruction for hire, when provided by the person giving the flight instruction, must also have received a 100-hour inspection. This inspection must be performed by an appropriately rated FAA certificated repair station, the aircraft manufacturer, or by an FAA certificated A&P mechanic. An annual inspection, or an inspection for the issuance of an Airworthiness Certificate, may be substituted for a required 100-hour inspection.

Preflight Inspections

The preflight inspection is a thorough and systematic means by which a pilot determines if the aircraft is airworthy and in condition for safe operation. The balloon’s Flight Manual contains a section devoted to a systematic method of performing a preflight inspection. For balloons, this inspection is usually a part of the layout and inflation process, and is greatly aided by the use of a checklist. Again, the pilot must also be aware of maximum damage limitations as published by the manufacturer.

Preventative Maintenance

Preventive maintenance is considered to be simple or minor preservation operations and the replacement of small standard parts, not involving complex assembly operations. Certificated pilots may perform preventive maintenance on any balloon that is owned or operated by them. According to 14 CFR part 43, appendix A, preventive maintenance may be performed by the owner/operator of an aircraft who holds at least an FAA Private Pilot Certificate with a balloon rating.

The following is a partial list of preventive maintenance that may be performed by the owner/operator of a balloon:

- Replacing defective safety wiring or cotter keys.

- Lubrication not requiring disassembly.

- The making of small fabric repairs to envelopes (as defined in, and in accordance with, the balloon manufacturers’ instructions) not requiring load tape repair or replacement.

- Refinishing decorative coating of the basket when removal or disassembly of any primary structure or operating system is not required.

- Applying preservative or protective material to components where no disassembly of any primary structure or operating system is involved and where such coating is not prohibited or is not contrary to good practices.

- Repairing upholstery and decorative furnishings of the balloon basket interior when the repairing does not require disassembly of any primary structure or operating system or interfere with an operating system or affect primary structure of the aircraft.

- Replacing seats or seat parts with replacement parts approved for the aircraft, not involving disassembly of any primary structure or operating system.

- Replacing prefabricated fuel lines.

- Replacing and servicing batteries.

- Cleaning of balloon burner pilots and main nozzles in accordance with balloon manufacturers’ instructions.

- Replacement or adjustment of nonstructural standard fasteners incidental to operations.

- The interchange of balloon baskets and burners on envelopes when the basket or burner is designated as interchangeable in the balloon Type Certificate Data Sheet (TCDS), and the baskets and burners are specifically designed for quick removal and installation.

Repairs and Alterations

Repairs and alterations are classified as either major or minor. 14 CFR part 43, appendix A, describes the alterations and repairs considered major. Major repairs or alterations shall be approved for return to service on FAA Form 337, Major Repair and Alteration, by an appropriately rated certificated repair station, an FAA certificated A&P mechanic holding an Inspection Authorization, or a representative of the Administrator. Minor repairs and minor alterations may be approved for return to service with a proper entry in the maintenance records by an appropriately certificated repair station or FAA certificated A&P mechanic.

For modifications of experimental aircraft, refer to the operating limitations issued to that aircraft. Modifications in accordance with FAA Order 8130.2, Airworthiness Certification of Aircraft and Related Products, may require the notification of the issuing authority.

Airworthiness Directives (ADs)

A primary safety function of the FAA is to require correction of unsafe conditions found in an aircraft, aircraft engine, propeller, or appliance when such conditions exist and are likely to exist or develop in other products of the same design. The unsafe condition may exist because of a design defect, maintenance, or other causes. 14 CFR part 39, Airworthiness Directives (ADs), define the authority and responsibility of the Administrator for requiring the necessary corrective action. ADs are the means used to notify aircraft owners and other interested persons of unsafe conditions and to specify

the conditions under which the product may continue to be operated. ADs may be divided into two categories:

- Those of an emergency nature requiring immediate compliance prior to further flight.

- Those of a less urgent nature requiring compliance within a specified period of time.

ADs are regulatory and shall be complied with unless a specific exemption is granted. It is the aircraft owner or operator’s responsibility to ensure compliance with all pertinent ADs. 14 CFR part 91, section 91.417 requires a record to be maintained that shows the current status of applicable ADs, including the method of compliance; the AD number and revision date, if recurring; the time and date when due again; the signature; kind of certificate; and certificate number of the repair station or mechanic who performed the work. For ready reference, many aircraft owners have a chronological listing of the pertinent ADs in the back of their aircraft maintenance records.

Choosing a Balloon

Many companies manufacture balloons that are type- certificated by the FAA. A type-certificated balloon has passed many tests, has been approved by the FAA, and conforms to the manufacturer’s TCDS. Balloon size is rated by envelope volume with categories defined in metric units. Figure 2-16 illustrates the most popular size ranges in use today (volumes are provided in cubic meters, as well as cubic feet).

Figure 2-16. Popular balloon size ranges.

Advantages of Balloon Sizes

Different balloon sizes offer different advantages. The size of the balloon purchased should be determined according to planned use(s). Most pilots think smaller balloons are easier to handle, fly, and pack up. Bigger balloons use less fuel, operate cooler, and last longer. Higher elevations or hotter climates or passengers indicate a larger balloon. Balloon competitions and sport flying require a smaller balloon. [Figure 2-17]

Figure 2-17. Comparison of balloon sizes.

Selecting a New or Used Balloon

The cost is the most obvious difference between new and used balloons. Some new pilots buy a used balloon to gain proficiency, and then purchase a new balloon when they have a better idea of what they want or need.

Prior to purchasing any used balloon, it is important to ensure that the balloon is airworthy, to avoid purchasing an aircraft which may be nearing, or perhaps past, its useful life. Most balloon envelopes are constructed of fabrics that last well into the 300–400 hour range, with some newer fabrics exceeding that life span. It would be prudent to have the balloon inspected by a reputable repair station or qualified inspector prior to purchase.

Balloon Brands

The level of after sales service available—locally and from the manufacturer—is an important criterion in deciding which brand of balloon to purchase. Talk to local pilots and ask questions. How does the local balloon repair station feel about different brands? Do they stock parts for only one brand? Does the manufacturer ship parts and fabric for balloons already in the field, or do they reserve these parts and fabric for new production? Do they ground older model balloons for lack of materials while new balloons are being built?

There are other criteria that could be considered, such as altitude at which the balloon will be flying, climate, and interchangeability of components, to give some examples. Before making the final decision, talk to people with different kinds of balloons who do different kinds of flying. Crewing for different balloons is an excellent way to learn about balloons and can help in the decision on what first balloon to purchase.

Chapter Summary

This chapter gives the reader common terminology for use in the ballooning community. Many times, confusion exists between the student pilot and the instructor, due to differences in terminology used, and it is hoped that the discussions here resolve those issues. The reader also should have an understanding of the physics of hot-air ballooning, as well as a good understanding of the support equipment involved with ballooning activities.

Propane information has also been included in this chapter, and it is recommended that all pilots review this on a recurring basis, perhaps as part of a yearly safety seminar. Additionally, proper documentation, and inspection requirements have been covered. Each pilot should become knowledgeable in these areas.