Introduction

FAA Involvement

The FAA has had a formal involvement in this issue since 1988. That was the year the first Human Factors Issues in Aviation Maintenance and Inspection National Conference was conducted, and that effort reflects a working relationship between government research and industry activity. This yearly event includes airlines, suppliers, manufacturers, schools, and government agencies. There is also an FAA website for human factors at hf.faa.gov which is a tremendous resource.

Importance of Human Factors

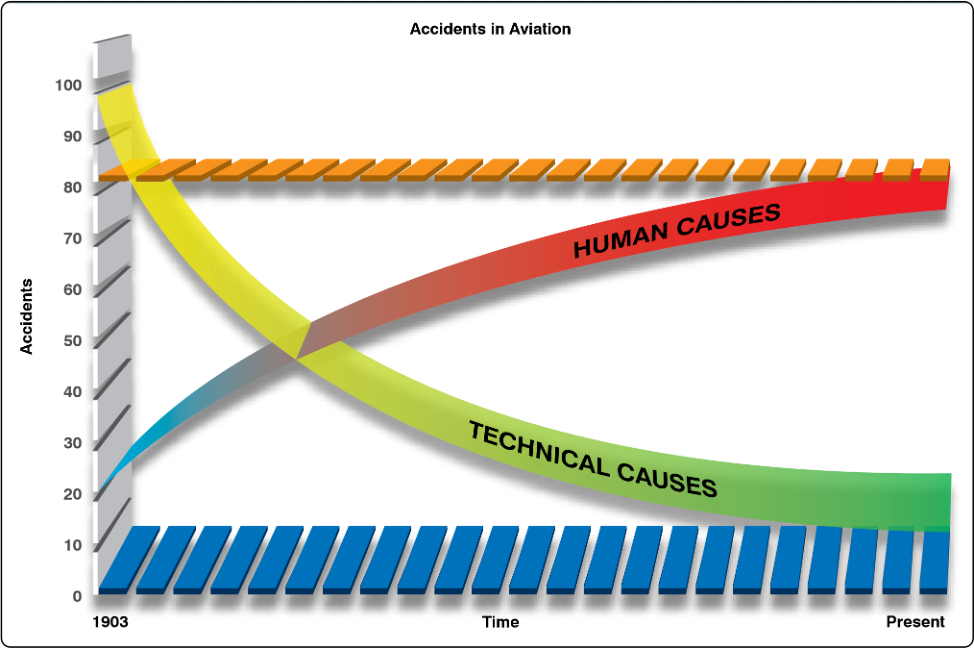

The greatest impact in aircraft safety in the future will not come from improving the technology. Rather it will be from educating the employee to recognize and prevent human error. A review of accident related data indicates that approximately 75–80 percent of all aviation accidents are the result of human error. Of those accidents, about 12 percent are maintenance related. Although pilot/co-pilot errors tend to have immediate and highly visible effects, maintenance errors tend to be more latent and less obvious. However, they can be just as lethal.

Definitions of Human Factors

Human factors are concerned with optimizing performance … including reducing errors so that the highest level of safety is achieved and maintained.

—Ron LoFaro, PhD

FAA

Human factors is the study of how people interact with their environments.

—FAA-H-8083-25,

Pilot’s Handbook of Aeronautical Knowledge

Human factors are those elements that affect our behavior and performance, especially those that may cause us to make errors.

—Canadian Department of Defense (video)

Our focus is on human factors as it relates to improper actions. Note, however, that human factors exist in both proper and improper actions. [Figure 14-1] Since improper actions usually result in human error, we should also define that term.

Human error is the unintentional act of performing a task incorrectly that can potentially degrade the system. There are three types of human error:

- Omission: not performing an act or task.

- Commission: accomplishing a task incorrectly.

- Extraneous: performing a task not authorized.

There are also four consequences of human error:

- Little or no effect.

- Damage to equipment/hardware.

- Personal injury.

- Catastrophic.

Why are human conditions, such as fatigue, complacency, and stress, so important in aviation maintenance? These conditions, along with many others, are called human factors. Human factors directly cause or contribute to many aviation accidents. It is universally agreed that 80 percent of maintenance errors involve human factors. If they are not detected, they can cause events, worker injuries, wasted time, and even accidents. [Figure 14-2]

Aviation safety relies heavily on maintenance. When it is not done correctly, it contributes to a significant proportion of aviation accidents and incidents. Some examples of maintenance errors are parts installed incorrectly, missing parts, and necessary checks not being performed. In comparison with many other threats to aviation safety, the mistakes of an aviation maintenance technician (AMT) can be more difficult to detect. Often, these mistakes are present but not visible and have the potential to remain latent, affecting the safe operation of aircraft for extended periods of time.

AMTs are confronted with a set of human factors unique within aviation. They can be working in the evening or early morning hours, in confined spaces, on high platforms, and in a variety of adverse temperature/humidity conditions. The work can be physically strenuous, yet it also requires attention to detail. [Figure 14-3] Because of the nature of maintenance tasks, AMTs commonly spend more time preparing for a task than actually carrying it out. Proper documentation of all maintenance work is a key element, and AMTs typically spend as much time updating maintenance logs as they do performing the work. [Figure 14-4]

Human factors awareness can lead to improved quality, an environment that ensures continuing worker and aircraft safety, and a more involved and responsible work force.

The reduction of even minor errors can provide measurable benefits including cost reductions, fewer missed deadlines, reduction in work related injuries, reduction of warranty claims, and reduction in more significant events that can be traced back to maintenance error. Within this chapter, the many aspects of human factors are discussed in relation to aviation maintenance. The most common human factors are introduced along with ways to mitigate the risk to stop them from developing into a problem. Several Federal Aviation Administration (FAA) human factor resources are provided, including a direct link to aviation maintenance human factors are at hf.faa.gov.

What are Human Factors?

The term “human factors” has grown increasingly popular as the commercial aviation industry realizes that human error, rather than mechanical failure, underlies most aviation accidents and incidents. Human factors science or technologies are multidisciplinary fields incorporating contributions from psychology, engineering, industrial design, statistics, operations research, and anthropometry. It is a term that covers the science of understanding the properties of human capability, the application of this understanding to the design, development, and deployment of systems

Figure . Human factors exist in both proper and improper actions.

Figure 14-2. Human factors and how they affect people are very important to aviation maintenance.

optimized by incorporating the many disciplines that affect human factors in an effort to understand how people can work more efficiently and maintain work performance.

By understanding each of the disciplines and applying them to different situations or human behaviors, we can correctly recognize potential human factors and address them before they develop into a problem or create a chain of problems that result in an accident or incident.

Clinical Psychology

Clinical psychology includes the study and application of psychology for the purpose of understanding, preventing, and relieving psychologically-based distress or dysfunction and to promote subjective well-being and personal development.

It focuses on the mental well-being of the individual. Clinical psychology can help individuals deal with stress, coping mechanisms for adverse situations, poor self-image, and accepting criticism from coworkers.

Experimental Psychology

Experimental psychology includes the study of a variety of basic behavioral processes, often in a laboratory environment.

These processes may include learning, sensation, perception, human performance, motivation, memory, language,

Figure . Aviation maintenance technicians (AMTs) are confronted with many human factors due to their work environments.

thinking, and communication, as well as the physiological processes underlying behaviors, such as eating, reading, and problem solving. In an effort to test the efficiency of work policies and procedures, experimental studies help measure performance, productivity, and deficiencies.

Anthropometry

Anthropometry is the study of the dimensions and abilities of the human body. This is essential to aviation maintenance due to the environment and spaces that AMTs have to work with.

For example, a man who is 6 feet 3 inches and weighs 230 pounds may be required to fit into a small crawl space of an aircraft to conduct a repair. Another example is the size and weight of equipment and tools. Men and women are generally on two different spectrums of height and weight. Although both are equally capable of completing the same task with a high level of proficiency, someone who is smaller may be able to perform more efficiently with tools and equipment tailored to their size. In other words, one size does not fit all and the term “average person” does not apply when employing such a diverse group of people.

Computer Science

The technical definition for computer science is the study of the theoretical foundations of information and computation and of practical techniques for their implementation and application in computer systems. Yet how this relates to aviation maintenance is simpler to explain. As mentioned earlier, AMTs spend as much time documenting repairs as they do performing them. It is important that they have computer work stations that are comfortable and reliable.

Software programs and computer-based test equipment should be easy to learn and use, and not intended only for those with a high levels of computer literacy.

Cognitive Science

Cognitive science is the interdisciplinary scientific study of minds as information processors. It includes research on how information is processed (in faculties such as perception, language, reasoning, and emotion), represented, and transformed in a nervous system or machine (e.g., computer).

It spans many levels of analysis from low-level learning and decision mechanisms to high-level logic and planning.

AMTs must possess a great ability to problem solve quickly and efficiently. They are constantly required to troubleshoot situations and quickly react to them. This can be a vicious cycle creating an enormous amount of stress. The discipline of cognitive science helps us understand how to better assist AMTs during situations that create high levels of stress so that their mental process does not get interrupted and affect their ability to work.

Safety Engineering

Safety engineering ensures that a life-critical system behaves as needed even when the component fails. Ideally, safety engineers take an early design of a system, analyze it to find what faults can occur, and then propose safety requirements in design specifications up front and changes to existing systems to make the system safer. Safety cannot be stressed enough when it comes to aviation maintenance, and everyone deserves to work in a safe environment.

Safety engineering plays a big role in the design of aviation maintenance facilities, storage containers for toxic materials, equipment used for heavy lifting, and floor designs to ensure no one slips, trips, or falls. In industrial work environments, the guidelines of the Occupational Safety and Health Administration (OSHA) are important.

Medical Science

Medicine is the science and art of healing. It encompasses a variety of health care practices evolved to maintain and restore health by the prevention and treatment of illness.

Disposition and physical well-being are very important and directly correlated to human factors. Just like people come in many shapes and sizes, they also have very different reactions to situations due to body physiology, physical structures, and biomechanics.

Organizational Psychology

Organizational psychologists are concerned with relations between people and work. Their interests include organizational structure and organizational change, workers’ productivity and job satisfaction, consumer behavior, and the selection, placement, training, and development of personnel. Understanding organizational psychology helps aviation maintenance supervisors learn about the points listed below that, if exercised, can enhance the work environment and productivity.

• Rewards and compensations for workers with good

Figure . A list of human factors that affect AMTs.

safety records.

- Motivation for workers to want to do well and work safely.

- Unifying work teams and groups so they get along and work together to get the job done right.

Treating all workers equally.

Educational Psychology

Educational psychologists study how people learn and design the methods and materials used to educate people of all ages. Everyone learns differently and at a different pace.

Supervisors should design blocks of instruction that relate to a wide variety of learning styles.

Industrial Engineering

Industrial engineering is the organized approach to the study of work. It is important for supervisors to set reasonable work standards that can be met and exceeded. Unrealistic work standards create unnecessary stressors that cause mistakes.

It is also beneficial to have an efficient facility layout so that there is room to work. Clean and uncluttered environments enhance work performance. Another aspect of industrial engineering that helps in the understanding of human factors is the statistical analysis of work performance. Concrete data of work performance, whether good or bad, can show the contributing factors that may have been present when the work was done.

Figure . Human factor disciplines.

History of Human Factors

Around 1487, Leonardo da Vinci began research in the area of anthropometrics. The Vitruvian Man, one of his most famous drawings, can be described as one of the earliest sources presenting guidelines for anthropometry.

[Figure 14-7] Around the same time, he also began to study the flight of birds. He grasped that humans are too heavy and not strong enough to fly using wings simply attached to the arms. Therefore, he sketched a device in which the aviator lies down on a plank and works two large, membranous wings using hand levers, foot pedals, and a system of pulleys. [Figure 14-87 Today, anthropometry plays a considerable role in the fields of computer design, design for access and maintainability, simplicity of instructions, and ergonomic issues.

In the early 1900s, industrial engineers Frank and Lillian Gilbreth were trying to reduce human error in medicine.

[Figures 14-9 and 14-10] They developed the concept of using call backs when communicating in the operating room. For example, the doctor says “scalpel” and the nurse repeats “scalpel” and then hands it to the doctor. That is called the challenge-response system. Speaking out loud reinforces what tool is needed and provides the doctor with an opportunity to make corrections if it is not the necessary tool.

This same verbal protocol is used in aviation today. Pilots are required to read back instructions or clearances given by air traffic control (ATC) to ensure that the pilot receives the correct instructions and gives ATC an opportunity to correct if the information is wrong. Frank and Lillian Gilbreth also are known for their research on fatigue.

Also in the early 1900s, Orville and Wilbur Wright were the first to fly a powered aircraft and also pioneered many human factors considerations. While others were trying to develop aircraft with a high degree of aerodynamic stability, the Wrights intentionally designed unstable aircraft with cerebralized control modeled after the flight of birds.

Between 1901 and 1903, the brothers worked with large gliders at Kill Devil Hills, near Kitty Hawk, North Carolina, to develop the first practical human interactive controls for aircraft pitch, roll, and yaw. On December 17, 1903, they made four controlled powered flights over the dunes at Kitty Hawk with their Wright Flyer. [Figure 14-11] They later developed practical in-flight control of engine power, plus an angle of attack sensor and stick pusher that reduced pilot workload. The brothers’ flight demonstrations in the United States and Europe during 1908-1909 awakened the world to the new age of controlled flight. Orville was the first aviator to use a seat belt and also introduced a rudder boost/ trim control that gave the pilot greater control authority. The Wrights’ flight training school in Dayton, Ohio included a flight simulator of their own design. The Wrights patented their practical airplane and flight control concepts, many of which are still in use today.

Prior to World War I, the only test of human to machine compatibility was that of trial and error. If the human functioned with the machine, he was accepted, if not he was rejected. There was a significant change in the concern for humans during the American Civil War. The U.S. Patent Office was concerned about whether the mass-produced uniforms and new weapons could be used effectively by the infantry men.

Evolution of Maintenance Human Factors

With the onset of World War I (1914-1918), more sophisticated equipment was being developed and the inability of personnel to use such systems led to an increased interest in human capability. Up to this point, the focus of aviation psychology was on the pilot, but as time progressed, the focus shifted onto the aircraft. Of particular concern was the design of the controls and displays, the effects of altitude, and environmental factors on the pilot. The war also brought on the need for aeromedical research and the need for testing and measurement methods. By the end of World War I, two aeronautical labs were established, one at Brooks Air Force Base, Texas, and the other at Wright Field outside of Dayton, Ohio.

Another significant development was in the civilian sector, where the effects of illumination on worker productivity were examined. This led to the identification of the Hawthorne Effect, which suggested that motivational factors could significantly influence human performance.

With the onset of World War II (1939-1945), it was becoming increasingly harder to match individuals to pre-existing jobs.

Now the design of equipment had to take into account human limitations and take advantage of human capabilities. This change took time as there was a lot of research still to be done to determine the human capabilities and limitations. An example of this is the 1947 study done by Fitts and Jones on the most effective configuration of control knobs to be used in aircraft flight decks. Much of this research transitioned into other equipment with the aim of making the controls and displays easier for the operators to use.

Unfortunately, all the “lessons learned” in the WWII studies of group dynamics, and flight crew communication were seemingly forgotten after the war. Post WWII aircrew studies continued to focus primarily on flight crews, especially pilot selection, simulator training, and cockpit layout and design.

Subsequent studies of the technician focused on individual competency and included equipment design (ergonomics).

Figure . Vitruvian Man, one of Leonardo da Vinci’s most famous anthropometric drawings.

Figure . Leonardo da Vinci’s rendering of a flying device for man.

The Vietnam Conflict brought the quest for greater safety, and with that, came a systematic approach for error reduction.

This increased attention brought both good and bad changes. It led to the “Zero Defects” quality programs in maintenance and manufacturing. Generally, this had a positive effect. However, it also led to “crackdown programs” which were one-way communication from management (the infamous “my way or the highway” approach). This concept is more

Figure . Frank Gilbreth – Industrial Engineer.

dictatorial than democratic, and typically had a long-term negative effect on the company. This “crackdown” approach for behavior control is based upon fear and punishment, which creates a problem. Errors are driven into hiding,

Figure . Lillian Gilbreth – Industrial Engineer.

and then become apparent later, usually at a more critical time (“Murphy’s Law”). Additional attempts to develop

“foolproof” equipment designs were added to the zero-defect manufacturing goal and began to find recognition in the maintenance world as well. Subsequent efforts focused on effects of positive rather than negative motivators. The results of this effort were a reversal of the “crackdown” method, and motivation due to increased morale often improved maintenance safety performance. Studies have shown that motivation resulting from negative sources seldom achieved the same effect. This led to a “Participative Management” style recognized by some U.S. industry and a few airlines, but did not reach maintenance operations until much later.

The Airline Deregulation (1978 -1988) effort had a profound effect upon the aviation community. Prior to 1978, the airline industry was regulated by the Civil Aeronautics Act of 1938. This resulted in peaceful markets, stable routes, and consistent air fares. However, there was a downside consisting of two major problems: wasteful management practices and excessively high wages compared to other comparable skilled-labor industries. The Airline Deregulation Act brought in competitive business practices, with routes and fares controlled by their profitability. This led to a new style of airline management in which a CEO was more of a business person and less knowledgeable of aviation. Existing airlines developed new routes and added new kinds of service and style. Start-up airlines brought other innovative ideas.

The numerous mergers and acquisitions added an increasing pressure to focus on the financial bottom line. Doing more with less became the byline. In the 1980s, maintenance departments were not immune to the pressures of mergers and staff reductions. However, fleets were extremely reliable at that time, and significant savings were aided by a reduction in number of maintenance technicians. Other new ways of conducting business included leasing of aircraft and outsourcing of maintenance. A result of deregulation was change for the maintenance programs (both personnel and departmental) and the pressure to produce and adjust.

The problem, however, was that human factors for aviation maintenance was still stuck in the 1960s model.

Figure . The Wright Brothers on December 17, 1903, flying over the dunes at Kitty Hawk with their Wright Flyer.

A detailed review of aviation literature published between 1976 and 1987 had very little to say about maintenance. Out of 50 published articles, only 15 even mention maintenance.

Most of these articles deal with ergonomics, one article examines military engine design to “solider proof” the maintenance duties, and one U.S. Navy article advocated more management control.

As human factors awareness progressed, a “culture change” occurred in U.S. carriers in the 1990s. Management behavior began to change; there were practical applications of systems thinking; organization structure was revised; and new strategy, policy, and values emerged. Virtually all of these involved communication and collaboration.

One example is in 1991, when Continental Airlines began

“CRM type” training in maintenance. They saw the importance of improving communication, teamwork, and participative decision making. A second example is when United Airlines instituted a change in organization and the job of design of inspectors. They remained more accessible during heavy maintenance and overhaul and stayed in closer communication with mechanics during normal repairs.

This resulted in fewer turnbacks and higher quality. A third example is when Southwest Airlines created and sustained a strong and clear organizational structure led by the CEO. This resulted in open and positive communication between the maintenance and other departments. A final example is when TWA instituted a new program to improve communication between the maintenance trade union and maintenance management. This resulted in improved quality.

The Pear Model

There are many concepts related to the science and practice of human factors. However, from a practical standpoint, it is most helpful to have a unified view, or a model of the things we should be concerned about when considering aviation maintenance human factors. For more than a decade, the term

“PEAR” has been used as a memory jogger, or mnemonic, to characterize human factors in aviation maintenance.

The PEAR mode prompts recall of the four important considerations for human factors programs, which are listed below.

- People who do the job.

- Environment in which they work.

- Actions they perform.

- Resources necessary to complete the job.

People

Aviation maintenance human factors programs focus on the people who perform the work and address physical, physiological, psychological, and psychosocial factors.

[Figure 14-12] The programs must focus on individuals, their physical capabilities, and the factors that affect them. They also should consider their mental state, cognitive capacity, and conditions that may affect their interaction with others. In most cases, human factors programs are designed around the people in the company’s existing workforce. You cannot apply identical strength, size, endurance, experience, motivation, and certification standards equally to all employees. The company must match the physical characteristics of each person to the tasks each performs.

The company must consider factors like each person’s size, strength, age, eyesight, and more to ensure each person is physically capable of performing all the tasks making up the job. A good human factors program considers the limitations of humans and designs the job accordingly. An important element when incorporating human factors into job design is planned rest breaks. People can suffer physical and mental fatigue under many work conditions. Adequate breaks and rest periods ensure the strain of the task does not overload their capabilities. Another “People” consideration, which also is related to “E” for “Environment,” is ensuring there is proper lighting for the task, especially for older workers. Annual vision testing and hearing exams are excellent proactive interventions to ensure optimal human physical performance.

Attention to the individual does not stop at physical abilities.

A good human factors program must address physiological and psychological factors that affect performance. Companies should do their best to foster good physical and mental health.

Offering educational programs on health and fitness is one way to encourage good health. Many companies have reduced sick leave and increased productivity by making healthy meals, snacks, and drinks available to their employees.

Companies also should have programs to address issues associated with chemical dependence, including tobacco and alcohol. Another “People” issue involves teamwork and communication. Safe and efficient companies find ways to foster communication and cooperation among workers, managers, and owners. For example, workers should be rewarded for finding ways to improve the system, eliminate waste, and help ensure continuing safety.

Environment

There are at least two environments in aviation maintenance.

There is the physical workplace on the ramp, in the hangar, or in the shop. In addition, there is the organizational environment that exists within the company. A human factors program must pay attention to both environments.

Physical

The physical environment is obvious. It includes ranges of temperature, humidity, lighting, noise control, cleanliness, and workplace design. Companies must acknowledge these conditions and cooperate with the workforce to either accommodate or change the physical environment. It takes a corporate commitment to address the physical environment.

This topic overlaps with the “Resources” component of

PEAR when it comes to providing portable heaters, coolers, lighting, clothing, and good workplace and task design.

Organizational

The second, less tangible, environment is the organizational one. The important factors in an organizational environment are typically related to cooperation, communication, shared values, mutual respect, and the culture of the company.

An excellent organizational environment is promoted with leadership, communication, and shared goals associated with safety, profitability, and other key factors. The best companies guide and support their people and foster a culture of safety. A safe culture is one where there is a shared value and attitude toward safety. In a safe culture, each person understands their individual role is contributing to overall mission safety.

Actions

Successful human factors programs carefully analyze all the actions people must perform to complete a job efficiently and safely. Job task analysis (JTA) is the standard human factors approach to identify the knowledge, skills, and attitudes necessary to perform each task in a given job.

The JTA helps identify what instructions, tools, and other resources are necessary. Adherence to the JTA helps ensure each worker is properly trained and each workplace has the necessary equipment and other resources to perform the job. Many regulatory authorities require that the JTA serve as the basis for the company’s general maintenance manual and training plan. Many human factors challenges associated with use of job cards and technical documentation fall under

“Actions.” Clearly understandable documentation of actions ensures instructions and checklists are correct and useable.

Resources

The final PEAR letter is “R” for “Resources.”

It is sometimes difficult to separate resources from the other elements of PEAR. In general, the characteristics of the people, environment, and actions dictate the resources.

Many resources are tangible, such as lifts, tools, test equipment, computers, technical manuals, and so forth. Other resources are less tangible. Examples include the number and qualifications of staff to complete a job, the amount of time allocated, and the level of communication among the crew, supervisors, vendors, and others. Resources should be viewed (and defined) from a broad perspective. A resource is anything a technician (or anyone else) needs to get the job done. For example, protective clothing is a resource. A mobile phone can be a resource. Rivets can be resources. What is important to the “Resource” element in PEAR is focusing on identifying the need for additional resources.

Another major human factors tool for use in investigation of maintenance problems is the Boeing developed Maintenance Error Decision Aid (MEDA). This is based on the idea that errors result from a series of factors or incidents. The goal of using MEDA is to investigate errors, understand root causes, and prevent accidents, instead of simply placing blame on the maintenance personnel for the errors. Traditional efforts to investigate errors are often designed to identify the employee who made the error. In this situation, the actual factors that

Figure . People who do the job.

contributed to the errors or accident remain unchanged, and the mistake is likely to recur. In an effort to break this “blame and train” cycle, MEDA investigators learn to look for the factors that contributed to the error, instead of the employee who made the error. The MEDA concept is based on the following three principles:

- Positive employee intent (In other words, maintenance technicians want to do the best job possible and do not make intentional errors.)

- Contribution of multiple factors (There is often a series of factors that contribute to an error.)

- Manageability of errors (Most of the factors that contribute to an error can be managed.)

When a company is willing to adopt these principles, then the MEDA process can be implemented to help the maintenance organization achieve the dual goals of identifying those factors that contribute to existing errors, and avoiding future errors. In creating this five-step process, Boeing initially worked with British Airways, Continental Airlines, United Airlines, a maintenance worker labor union, and the FAA.

The five steps are:

- Event: the maintenance organization must select which error that caused events will be investigated.

- Decision: was the event maintenance related? If the answer is yes, then the MEDA investigation continues.

- Investigation: using the MEDA results form, the operator conducts an investigation to record general information about the airplane-when the maintenance and the event occurred, what event initiated the investigation, the error that caused the event, the factors contributing to the error, and a list of possible presentation strategies.

- Prevention strategies: the operator reviews, prioritizes, implements, and then tracks the process improvements (prevention strategies) in order to avoid or reduce the likelihood of similar errors in the future.

- Feedback: the operator provides feedback to the maintenance workplace so technicians know that changes have been made to the maintenance system as a result of this MEDA process.

The implantation and continuous use of MEDA is a long-term commitment and not a “quick fix.” However, airline operators and maintenance facilities frequently decide to use the MEDA approach to investigate serious, high visibility events which have caused significant cost to the company.

The desire to do this is based upon the potential “payback” of such an investigation.

This may ultimately be counterproductive because a highly visible event may not really be the best opportunity to investigate errors. Those involved in the process may be intimidated by the attention coming from upper management and various regulatory authorities.

By using the MEDA process properly, the organization can investigate the factors that contributed to an error, discover exactly what led to that error, and fix those factors. Successful implementation of MEDA will allow the organization to avoid rework, lost revenue, and potentially dangerous situations related to events caused by maintenance errors.

The “SHEL” model is another concept for investigating and evaluating maintenance errors. [Figure 14-16] As with other human factors tools, its goal is to determine not only what the problem is, but where and why it exists. SHEL was initiated by Professor Elwyn Edwards (Professor Emeritus, Aston University, Birmingham, U.K.) in 1972. It was later modified slightly by the late Capt. Frank Hawkins, a Human Factors consultant to KLM, in 1975. The acronym SHEL represents:

- Software

- Hardware

Figure . Environment in which they work.

Figure . Actions they perform.

Figure . Resources necessary to complete the job.

- Environment

- Liveware

The model examines interaction with each of the four SHEL components, and does not consider interactions not involving human factors. The term “software” is not referring to the common use of the term as applied to computer programs.

Instead it includes a broader view of manual layout, checklist layout, symbology, language (both technical and nontechnical), and computer programs. Hardware includes such things as the location of components, the accessibility of components and tooling. Environment takes temperature, humidity, sound, light, and time of day factors into account.

Liveware relates technician interaction with other people, both on the job and off. These include managers, peers, family, friends, and self.

No discussion of human factors is complete without reference to James Reasons’ Model of Accident Causation. This diagram, which was introduced in 1990, and revised by Dr.

Reason in 1993, is often referred to as the Swiss cheese model and shows how various “holes” in different systems must be aligned in order for an error to occur. Only when the holes are all aligned can the incident take place.

There are two types of failure which can occur-active and latent. An active failure is one in which the effects are immediate. An example of this type would be an aircraft slipping off one of the lifting jacks due to improper placement by the technician. In this example, the aircraft jack is the approved item of ground support equipment, and it has been properly maintained.

A latent failure occurs as a result of a decision or action made long before the incident or accident actually occurs.

The consequences of such a decision may remain dormant for a long time. An example of a latent failure could also involve the aircraft slipping off a joint, but in this case, it could be an unapproved jack being used because funding had not been approved to purchase the correct ground support equipment (GSE).

The field of human factors, especially in aviation maintenance, is a growing field of study. This section of this chapter has presented only a small segment of the numerous observations and presentations about the topic. If the technician desires to learn more, numerous books exist and a review of Internet data will provide an abundant supply of information.

A good place to start researching would be the FAA’s own website at hf.faa.gov. This site, titled “Human Factors on Aviation Maintenance and Inspection (HFAMI)” provides access to products of the Federal Aviation Administration Flight Standards Service Human Factors in Aviation Maintenance and Inspection Program. Many aviation maintenance industry trade magazines include a section or at least a page devoted to human factors. “The Human Factors and Ergonomics Society” is a national organization composed of 22 technical groups, including one devoted to aerospace systems, which address both civilian and military issues of safety and performance.

Human Error

Human error is defined as a human action with unintended consequences. When you couple error with aviation maintenance and the negative consequences that it produces, it becomes extremely troublesome. Training, risk assessments, safety inspections, etc., should not be restricted to an attempt to avoid errors but rather to make them visible and identify them before they produce damaging and regrettable consequences. Simply put, human error is not avoidable but it is manageable. [Figure 14-17]

Types of Errors

Unintentional

An unintentional error is an accidental wandering or deviation from accuracy. This can include an error in your action (a slip), opinion, or judgment caused by poor reasoning, carelessness, or insufficient knowledge (a mistake). For example, an AMT reads the torque values from a job card and unintentionally transposed the number 26 to 62. They did not mean to make that error but unknowingly and unintentionally did. An example of an unintentional mistake would be selecting the wrong work card to conduct a specific repair or task. Again, it is not an intentional mistake but a mistake nonetheless.

Intentional

In aviation maintenance, an intentional error should really be considered a violation. If someone knowingly or intentionally chooses to do something wrong, it is a violation, which means that one has purposely deviated from safe practices, procedures, standards, or regulations.

Active & Latent

An active error is the specific individual activity that is an obvious event. A latent error is the company issues that lead up to the event. For example, an AMT climbs up a ladder to do a repair knowing that the ladder is broken. In this example, the active error was falling from the ladder. The latent error was the broken ladder that someone should have replaced.

Figure . SHEL model.

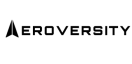

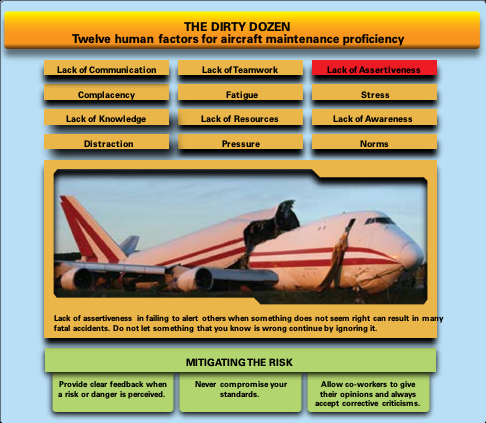

The “Dirty Dozen”

Due to a large number of maintenance-related aviation accidents and incidents that occurred in the late 1980s and early 1990s, Transport Canada identified twelve human factors that degrade people’s ability to perform effectively and safely, which could lead to maintenance errors. These twelve factors, known as the “dirty dozen,” were eventually adopted by the aviation industry as a straightforward means to discuss human error in maintenance. It is important to know the dirty dozen, how to recognize their symptoms, and most importantly, know how to avoid or contain errors produced by the dirty dozen. Understanding the interaction between organizational, work group, and individual factors that may lead to errors and accidents, AMTs can learn to prevent or manage them proactively in the future.

Lack of Communication

Lack of communication is a key human factor that can result in suboptimal, incorrect, or faulty maintenance.

Communication occurs between the AMT and many people (i.e., management, pilots, parts suppliers, aircraft servicers). Each exchange holds the potential for misunderstanding or omission. But communication between AMTs may be the most important of all. Lack of communication between technicians could lead to a maintenance error and result in an aircraft accident. This is especially true during procedures where more than one technician performs the work on the aircraft. It is critical that accurate, complete information be exchanged to ensure that all work is completed without any step being omitted.

Knowledge and speculation about a task must be clarified and not confused. Each step of the maintenance procedure must be performed according to approved instructions as though only a single technician did the work.

A common scenario where communication is critical and a lack thereof can cause problems, is during shift change in an airline or fixed base operator (FBO) operation. A partially completed job is transferred from the technician finishing their workday to the technician coming on duty. Many steps in a maintenance procedure are not able to be seen or verified once completed due to the installation of components hiding the work. No steps in the procedure can be omitted and some steps still to be performed may be contingent on the work already completed. The departing technician must thoroughly explain what has occurred so that the arriving technician can correctly complete the job. A recounting of critical steps and any difficulties encountered gives insight.

A lack of communication at this juncture could result in the work being continued without certain required operations having been performed.

The approved steps of a maintenance procedure must be signed off by the technician doing the work as it is performed.

Continuing a job that has been started by someone else should only occur after a face-to-face meeting of technicians. The applicable paperwork should be reviewed, the completed work discussed, and attention drawing to the next step.

Absence of either a written or oral turnover serves as warning that an error could occur.

It is vital that work not be continued on a project without both oral and written communication between the technician who started the job and the technician continuing it. Work should always be done in accordance with the approved written procedure and all of the performed steps should bear the signature of the technician who accomplishes the work. If necessary, a phone call can be made to obtain an oral turnover when technicians cannot meet face-to-face at the work area. In general, the technician must see their role as part of a greater system focused on safe aircraft operation and must communicate well with all those in that system to be effective.

Complacency

Complacency is a human factor in aviation maintenance that typically develops over time. [Figure 14-18] As a technician gains knowledge and experience, a sense of self satisfaction and false confidence may occur. A repetitive task, especially an inspection item, may be overlooked or skipped because the technician has performed the task a number of times without ever finding a fault. The false assumption might be made that inspection of the item is not important. However, even if rare, a fault may exist. The consequences of the fault not being detected and corrected could cause an incident or accident. Routine tasks performed over and over allow time for the technician’s mind to wander, which may also result in a required task not being performed.

Figure . Safety awareness will help foresee and mitigate the risk of human error.

When a technician performs work without documentation, or documents work that was not performed, it is a sign that complacency may exist. Approved, written maintenance procedures should be followed during all maintenance inspections and repairs. Executing the proper paperwork draws attention to a work item and reinforces its significance.

To combat complacency, a technician must be trained to expect to find the fault that created the inspection item in the first place. The technician must stay mentally engaged in the task being performed. All inspection items must be treated with equal importance, and it must never be assumed that an item is acceptable when it has not been inspected.

A technician should never sign for any work that has not been performed. Prior to the pen touching the paper for a signature, the technician should read the item before signing and confirm it has been performed.

Lack of Knowledge

A lack of knowledge when performing aircraft maintenance can result in a faulty repair that can have catastrophic results.

Differences in technology from aircraft to aircraft and updates to technology and procedures on a single aircraft also make it challenging to obtain the knowledge required to perform airworthy maintenance.

All maintenance must be performed to standards specified in approved instructions. These instructions are based on knowledge gained from the engineering and operation of the aircraft equipment. Technicians must be sure to use the latest applicable data and follow each step of the procedure as outlined. They must also be aware that differences exist in the design and maintenance procedures on different aircraft.

It is important for technicians to obtain training on different types of aircraft. When in doubt, a technician with experience on the aircraft should be consulted. If one is not available, or the consulted technician is not familiar with the procedure, a manufacturer’s technical representative should be contacted. It is better to delay a maintenance procedure than to do it incorrectly and cause an accident.

Distraction

A distraction while performing maintenance on an aircraft may disrupt the procedure. When work resumes, it is possible that the technician skips over a detail that needs attention. It is estimated that 15 percent of maintenance related errors are caused by distractions.

Distractions can be mental or physical in nature. They can occur when the work is located on the aircraft or in the hangar. They can also occur in the psyche of the technician independent of the work environment. Something as simple as a cell phone call or a new aircraft being pushed into the

Figure . Lack of communication.

hangar can disrupt the technician’s concentration on a job.

Less visible is a difficult family or financial matter or other personal issues that may occupy the technician’s thought process as work is performed. This can make performance of the required maintenance less effective.

Whatever their nature, numerous distractions can occur during the course of maintaining an aircraft. The technician must recognize when attention to the job at hand is being diverted and assure that work continues correctly. A good practice is to go back three steps in the work procedure from when distraction occurred and resume the job from that point. Using of a detailed step-by-step written procedure and signing off each step only after it is completed also helps. Incomplete work can be marked or tagged, especially when the technician is pulled from the work by a distraction, and it is unknown when work will be resumed and by whom. Disconnect any connector and leave it plainly visible if an installation is not complete. There is a tendency to think a job is finished when a component is “hooked up.” Similarly, when a step in the maintenance procedure is complete, be sure to immediately lock wire or torque the fasteners if required. This can be used as an indication that all is well up to that point in the procedure.

Lack of Teamwork

A lack of teamwork may also contribute to errors in aircraft maintenance. [Figure 14-22] Closely related to the need for communication, teamwork is required in aviation maintenance in many instances. Sharing of knowledge between technicians, coordinating maintenance functions, turning work over from shift to shift, and working with flight personnel to troubleshoot and test aircraft are all are executed better in an atmosphere of teamwork. Often associated with improved safety in the workplace, teamwork involves everyone understanding and agreeing on actions to be taken. A gear swing or other operational check involves all the members of a team working together. Multiple technicians contribute to the effort to ensure a single outcome. They communicate and look out for one another as they do the job. A consensus is formed that the item is airworthy or not airworthy.

The technician primarily deals with the physical aspect of the aircraft and its airworthiness. Others in the organization perform their roles and the entire company functions as a team. Teams can win or lose depending on how well everyone in the organization works together toward a common objective. A lack of teamwork makes all jobs more difficult and, in maintenance, could result in a miscommunication that affects the airworthiness of the aircraft.

Fatigue

Fatigue is a major human factor that has contributed to many maintenance errors resulting in accidents. Fatigue can be mental or physical in nature. Emotional fatigue also exists and affects mental and physical performance. A person is said to be fatigued when a reduction or impairment in any of the following occurs: cognitive ability, decision-making, reaction time, coordination, speed, strength, or balance. Fatigue reduces alertness and often reduces a person’s ability to focus on the task being performed.

Symptoms of fatigue can also include short-term memory problems, channeled concentration on unimportant issues while neglecting more important ones, and failure to maintain a situational overview. A fatigued person may be easily distracted or may be nearly impossible to distract. They may experience abnormal mood swings. Fatigue results in an increase in mistakes, poor judgment, and poor decisions or perhaps no decisions at all. A fatigued person may also lower their standards.

Tiredness is a symptom of fatigue. However, sometimes a fatigued person may feel wide awake and engaged in a task.

The primary cause of fatigue is a lack of sleep. Good restful sleep, free from drugs or alcohol is a human necessity to prevent fatigue. Fatigue can also be caused by stress and overworking. A person’s mental and physical state also naturally cycles through various levels of performance each day. Variables such as body temperature, blood pressure, heart rate, blood chemistry, alertness, and attention rise and fall in a pattern daily. This is known as circadian rhythm.

[Figure 14-24] A person’s ability to work (and rest) rises and falls during this cycle, and performance counter to circadian rhythm can be difficult. Until it becomes extreme, a person may be unaware that they are fatigued. It is easier recognized by another person or in the results of tasks being performed.

This is particularly dangerous in aviation maintenance since the lives of people depend on maintenance procedures performed at a high level of proficiency. Working alone when fatigued is particularly dangerous.

The best remedy for fatigue is to get enough sleep on a regular basis. The technician must be aware of the amount and quality of sleep obtained. Time off is justified when too little sleep has occurred and errors are probable during maintenance. Countermeasures to fatigue are often used, but their effectiveness can be short lived and many can make fatigue worse. Caffeine is a common fatigue countermeasure.

Pseudoephedrine found in sinus medicine and amphetamines are also used. While they can be effective for short periods, the underlying fatigue remains and due to this drug use, the person may have trouble getting the rest needed once off the job.

Suggestions to help mitigate the problems caused by fatigue include looking for symptoms of fatigue in oneself and in

Figure . Complacency.

others. Have others check your work, even if an inspector sign off is not required. Avoid complex tasks during the bottom of your circadian rhythm. Sleep and exercise daily. Eight to nine hours of daily sleep are recommended to avoid fatigue.

AMTs in airline operations are part of a system in which most maintenance is performed at night. Fleet aircraft are operated primarily during daytime hours to generate company revenue. Therefore, shift work is required to maintain the fleet. It is already known that turning work over to other technicians during shift changes can lead to errors due to lack of communication. But shift work alone is a cause of fatigue that can degrade performance and also lead to errors.

Shift work requires technicians to work during low cycles of their natural circadian rhythm. It also makes sleep more difficult when not on the job. Furthermore, regular night shift work makes a person’s body more sensitive to environmental disturbances. It can degrade performance, morale, and safety. It can also affect one’s physical health. All of these can be reflected in degraded maintenance performance-a dangerous situation.

The technician must be aware that shift work is the norm in

Figure . Lack of knowledge.

aviation. Avoidance of fatigue is part of the job. Title 14 of the Code of Federal Regulations (14 CFR) part 121, section 377, only requires 24 hours time off during a week of work.

Since this is obviously not enough, it is up to companies and technicians to regulate shift work and time off to reduce the potential for errors. Most importantly, each technician must monitor and control their sleep habits to avoid fatigue.

Lack of Resources

A lack of resources can interfere with a person’s ability to complete a task because of a lack of supplies and support.

Low quality products also affect one’s ability to complete a task. Aviation maintenance demands proper tools and parts to maintain a fleet of aircraft. Any lack of resources to safely carry out a maintenance task can cause both non-fatal and fatal accidents. For example, if an aircraft is dispatched without a functioning system that is typically nonessential for flight but suddenly becomes needed, this could create a problem.

Figure . Distraction.

Parts are not the only resources needed to do a job properly, but all too frequently parts become a critical issue. AMTs can try to be proactive by checking suspected areas or tasks that may require parts at the beginning of the inspection. Aircraft on ground (AOG) is a term in aviation maintenance indicating that a problem is serious enough to prevent an aircraft from flying. In these cases, there is a rush to acquire the parts to put the aircraft back into service and prevent further delays or cancellations of the planned itinerary. AOG applies to any aviation materials or spare parts that are needed immediately for an aircraft to return to service. AOG suppliers refer qualified personnel and dispatch the parts required to repair the aircraft for an immediate return to service. AOG also is used to describe critical shipments for parts or materials for aircraft “out of service” (OTS) at a location. If the status of an aircraft is AOG and materials required are not on hand, parts and personnel must be driven, flown, or

Figure . Lack of teamwork.

sailed to the location of the grounded aircraft. Usually the problem is escalated through an internal AOG desk, then the manufacturer’s AOG desk, and finally competitors’ AOG desks. All major air carriers have an AOG desk that is manned 24 hours a day, 7 days a week by personnel trained in purchasing, hazardous materials shipping, and parts manufacturing and acquisition processes.

Within an organization, making sure that personnel have the correct tools for the job is just as important as having the

proper parts when they are needed. Having the correct tools means not having to improvise. For example, an aircraft that had received a new interior needed to be weighed prior to being released to fly. Two days before the planned release, the aircraft was weighed without the proper electronic load cells placed between the aircraft jack and the aircraft. Because the correct equipment was not used, the aircraft slipped off of one of the load cells and the jack point creased the spar. The cost of improvising can be very steep. The right tools for the job need to be used at all times, and if they are broken, out of

Figure . Fatigue.

calibration, or missing, they need to be repaired, calibrated, or found as soon as possible.

Technical documentation is another critical resource that can lead to problems in aviation maintenance. When trying to find out more about the task at hand or how to troubleshoot and repair a system, the needed information often cannot be found because the manuals or diagrams are not available.

If the information is unavailable, personnel should ask a supervisor or speak with a technical representative or technical publications department at the appropriate aircraft manufacturer. Most manuals are in a constant state of revision and, if organizations do not identify missing information in the manuals, then nothing is done to correct the documentation. Resources such as publications departments and manufacturers’ technical support are available and should be used rather than ignoring the problem. Another valuable resource that the maintenance department should rely on is the flight crew. Organizations should

Figure . Many human variables rise and fall daily due to one’s natural circadian rhythm.

encourage open communication between flight crews and maintenance crews. The flight crew can provide valuable information when dealing with a defective part or problem.

Figure 14-26 shows a number of questions that flight crews can be asked to help resolve and understand maintenance issues.

When the proper resources are available for the task at hand, there is a much higher probability that maintenance will do a better, more efficient job and higher likelihood that the job will be done correctly the first time. Organizations must learn to use all of the resources that are available and, if the correct resources are not available, make the necessary arrangements to get them in a timely manner. The end result saves time and money, and enables organizations to complete the task knowing the aircraft is airworthy.

Pressure

Aviation maintenance tasks require individuals to perform in an environment with constant pressure to do things better and faster without making mistakes and letting things fall through the cracks. Unfortunately, these types of job pressures can affect the capabilities of maintenance workers to get the job done right. [Figure 14-27] Airlines have strict financial guidelines, as well as tight flight schedules, that pressure mechanics to identify and repair mechanical problems quickly so that the airline industry can keep moving. Most important, aircraft mechanics are responsible for the overall safety of everyone who uses flying as a mode of transportation.

Organizations must be aware of the time pressures that are put on aircraft mechanics and help them manage all of the tasks that need to be completed so that all repairs, while done in a timely manner, are completed correctly with safety being the ultimate goal. Sacrificing quality and safety for the sake of time should not be tolerated or accepted. Likewise, AMTs need to recognize on their own when time pressures are clouding their judgments and causing them to make unnecessary mistakes.

Self-induced pressures are those occasions where one takes ownership of a situation that was not of their doing.

In an effort to combat self-induced pressure, technicians should ask for help if they feel overwhelmed and under a time constraint to complete a repair. Another method is to have someone check the repair thoroughly to ensure that all maintenance tasks were completed correctly.

Lastly, if given a repair with a specific time limitation that you feel is unrealistic or compromises safety, bring it to the attention of the organization’s management and openly discuss a different course of action.

Lack of Assertiveness

Assertiveness is the ability to express your feelings, opinions, beliefs, and needs in a positive, productive manner and should not be confused with being aggressive. [Figure 14-28] It is important for AMTs to be assertive in issues relating to aviation repair rather than choosing not to or not being allowed to voice their concerns and opinions. Not being assertive could ultimately cost people their lives. The following are examples of how a lack of assertiveness can be offset:

1. Address managers and supervisors directly by stating the problem.

Example: “John, I have a concern with how this repair is being rushed.”

Figure . Lack of resources.

- Explain what the consequences will be. Example: “If we continue, the result will be that the part will break sooner rather than later.”

- Propose possible solutions to the problem. Example: “We could try doing things another way or you may want to try this way.”

- Always solicit feedback and include other opinions

Example: “John, what do you think?”

When being assertive with co-workers or management, deal with one issue at a time rather than trying to tackle a number of problems at once. It is also important to have documentation and facts to back up your argument, which can give people a visual account of what you are trying to explain. A lack of assertiveness in failing to speak up when things do not seem right has resulted in many fatal accidents. This can easily be changed by promoting good communication between co-workers and having an open relationship with supervisors and management. Maintenance managers must be familiar with the behavior styles of the people they supervise and learn to utilize their talents, experience, and wisdom. As the employees become aware of behavior styles and understand their own behavior, they see how they unwittingly contribute to some of their own problems and how they can make adjustments. Assertive behavior may not be a skill that comes naturally to every individual, but it is a critical skill to achieve effectiveness. AMTs should give supervisors and management the kind of feedback required to ensure that they will be able to assist mechanics in doing their job.

Stress

Aviation maintenance is a stressful task due to many factors. [Figure 14-29] Aircraft must be functional and flying in order for airlines to make money, which means that maintenance must be done within a short timeframe to avoid flight delays and cancellations. Fast-paced technology that is always changing can add stress to technicians. This demands that AMTs stay trained on the latest equipment. Other stressors include working in dark, tight spaces, lack of resources to get the repair done correctly, and long hours. The ultimate stress of aviation maintenance is knowing that the work they do, if not done correctly, could result in tragedy.

Everyone handles stress differently and particular situations can bring about different degrees of difficulty for different people. For example, working under a strict timeline can be a stressor for one person and normal for another. The causes of stress are referred to as “stressors” and are categorized as physical, psychological, or physiological. Following is a list of each and how they may affect maintenance.

Physical Stressors

Physical stressors add to a person’s workload and make their work environment uncomfortable.

- Temperature—high temperatures in the hangar increase perspiration and heart rate causing the body to overheat. Low temperatures can cause the body to feel cold, weak, and drowsy.

- Noise—hangars that have high noise levels (due to aircraft taking off and landing close by) can make it difficult for maintenance personnel to focus and concentrate.

- Lighting—poor lighting within a work space makes it difficult to read technical data and manuals. Likewise, working inside an aircraft with poor lighting increases the propensity to miss something or to repair something incorrectly.

- Confined spaces—small work spaces make it very

Figure . Questions that technicians can ask flight crews in an effort to resolve and understand maintenance issues.

difficult to perform tasks, as technicians are often contorted into unusual positions for a long period of time.

Psychological Stressors

Psychological stressors relate to emotional factors, such as a death or illness in the family; business worries; poor interpersonal relationships with family, co-workers, or supervisors; and financial worries.

- Work-related stressors—over anxiousness can hinder performance and speed while conducting maintenance if there is any apprehension about how to do a repair or concerns about getting it done on time.

- Financial problems—impending bankruptcy, recession, loans, and mortgages are a few examples of financial problems that can create stressors.

- Marital problems—divorce and strained relationships can interfere with one’s ability to perform their job correctly.

- Interpersonal problems—problems with superiors and colleagues due to miscommunication or perceived competition and backstabbing can cause a hostile work environment.

Figure . Pressure.

Physiological Stressors

Physiological stressors include fatigue, poor physical condition, hunger, and disease.

- Poor physical condition—trying to work when ill or not feeling well can force the body to use more energy fighting the illness, leaving less energy to perform vital tasks.

- Proper meals—not eating enough, or eating foods lacking the proper nutrition, can result in low energy and induce symptoms like headaches and shaking.

- Lack of sleep—a fatigued AMT is unable to perform to standard for long periods of time and can become sloppy with repairs and make significant mistakes.

- Conflicting shift schedules—the effect of changing sleep patterns on the body’s circadian cycle can lead to a degradation of performance.

Figure . Lack of assertiveness.

People cope with stress in many different ways. Specialists say that the first step is to identify stressors and the symptoms that occur after exposure to those stressors. Other recommendations involve development or maintenance of a healthy lifestyle with adequate rest and exercise, a healthy diet, limited consumption of alcoholic drinks, and avoidance of tobacco products.

Lack of Awareness

Lack of awareness is defined as a failure to recognize all the consequences of an action or lack of foresight. In aviation maintenance, it is not unusual to perform the same maintenance tasks repeatedly. After completing the same task multiple times, it is easy for technicians to become less vigilant and develop a lack of awareness of what they are doing and what is around them. Each time a task is completed it must be treated as if it were the first time.

Norms

Norms is short for “normal,” or the way things are normally done. They are unwritten rules that are followed or tolerated by most organizations. Negative norms can detract from the established safety standard and cause an accident to occur. Norms are usually developed to solve problems that have ambiguous solutions. When faced with an ambiguous situation, an individual may use another’s behavior as a frame of reference around which to form their own reactions. As this process continues, group norms develop and stabilize. Newcomers to the situation are then accepted into the group based on adherence to norms. Very rarely do newcomers initiate change in a group with established norms.

Some norms are unsafe in that they are non-productive or detract from the productivity of the group. Taking shortcuts ine to identify these unsafe norms

aircraft maintenance, working from memory, or not following procedures are examples of unsafe norms. Newcomers are better able to identify these unsafe norms than long-standing members of the group. On the other hand, the newcomer’s credibility depends on their assimilation into the group. The newcomer’s assimilation, however, depends on adherence to the group norms. Everyone should be aware of the perceptiveness of newcomers in identifying unhealthy norms and develop a positive attitude toward the possibility that norms may need to be changed. Finally, as newcomers become assimilated into the group structure, they build credibility with others. Once this has been done, a relative newcomer may begin to institute change within the group. Unfortunately, such actions are often difficult to do and rely heavily on the group’s perception of the newcomer’s credibility.

Norms have been identified as one of the dirty dozen in aviation maintenance and a great deal of anecdotal evidence points to the use of unsafe norms on the line. The effect of unsafe norms may range from the relatively benign, such as determining accepted meeting times, to the inherently unsafe, such as signing off on incomplete maintenance tasks. Any behavior commonly accepted by the group, whether as a standard operating procedure (SOP) or not, can be a norm. Supervisors need to ensure that everyone adheres to the same standards and that unsafe norms are not tolerated. AMTs should pride themselves on following procedure, rather than unsafe norms that may have been adopted as regular practice.

Figure . Stress.

Figure . Lack of awareness.

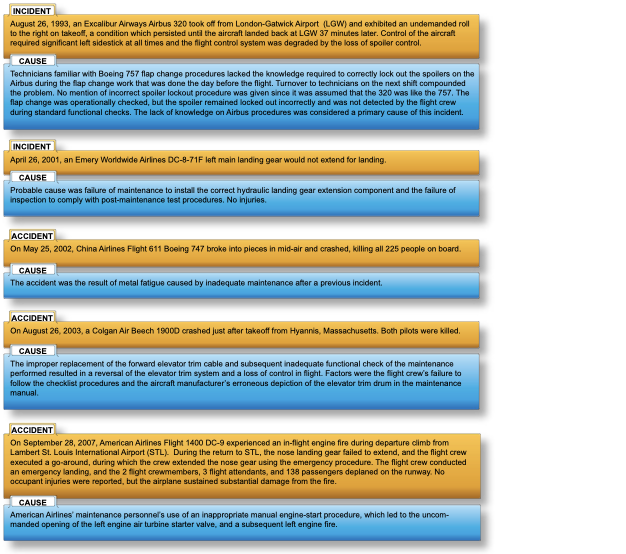

Example of Common Maintenance Errors

In an effort to identify the most frequently occurring maintenance discrepancies, the United Kingdom Civil Aviation Authority (CAA) conducted in-depth studies of maintenance sites on aviation maintenance operations. The following list is what they found to be the most common occurring maintenance errors.

- Incorrect installation of components.

- Fitting of wrong parts.

- Electrical wiring discrepancies to include crossing connections.

- Forgotten tools and parts.

- Failure to lubricate

- Failure to secure access panels, fairings, or cowlings.

- Fuel or oil caps and fuel panels not secured.

- Failure to remove lock pins.

All of the maintenance discrepancies listed above can be avoided if the proper procedures are followed on the job card that is being used. [Figure 14-35] Regardless of how many times the task has been completed, each time you

Figure . Norms.

pick up a job card, treat it like it is the first time you have ever completed the task, and complete it with diligence and complete accuracy.

Historically, twenty percent of all accidents are caused by a machine failure, and eighty percent by human factors. [Figure 14-36] Originally focusing on the pilot community, human factors awareness has now spread into the training sphere of maintenance technicians. An in-depth review of an aviation incident reveals time and again that a series of human errors (known also as a chain of events) was allowed to build until the accident occurred. If the chain of events is

broken at the maintenance level, the likelihood of the accident occurring can be drastically decreased. Figure 14-37 is a list of maintenance-related incidents/accidents and their causes. It is easy to see how many of the “Dirty Dozen” contributed to the causes or were considered contributing factors.

Where to Get Information

Following is a list of websites and references that are good sources of information on human factors.

Figure . A description of a Lufthansa Airbus A320 that almost crashed due to reversed wiring of the flight controls.

Figure . A description of Alaska Airlines Flight 261 that crashed due to insufficient lubrication of the jackscrew assembly

Federal Aviation Administration (FAA)

There are a number of human factors resources within the FAA. The most direct link for aviation maintenance human factors is the FAA Human Factors website at hf.faa.gov. It offers document access and services, including most of the FAA maintenance human factors documents dating back to the 1988 start of FAA’s maintenance human factors research and development program. New documents include videos, PowerPoint presentations, and other media.

Figure . Lock pins located on the landing gear of an aircraft.

Figure . A sample picture of a maintenance job card that explains the steps of each maintenance task.

FAA’s Maintenance Fatigue Section

The FAA has sponsored a multi-disciplinary subject matter expert work group involving industry, labor, research, and government to investigate the issues associated with maintenance fatigue, and the practical science-based methods that can be used to manage fatigue risk. For more information, visit the website at www.mxfatigue.com.

Figure . Statistical illustration showing that 80 percent of all aviation accidents are caused by human factors.

FAA Safety Team

The FAA Safety Team has a dedicated website that provides up-to-date information safety concerns, upcoming seminars, featured courses and resources. For more information, visit the website at www.faasafety.gov.

Other Resources

System Safety Services

The mission of System Safety Services is to assist clients in developing the best possible safety system to meet their needs. They have an experienced and professional team of individuals with years of experience in aviation and human factors. The website provides a lot of information on human factors including articles, upcoming events, presentations, safety videos, training aids and workshops. For more information, visit their website at www.system-safety.com.

Human Factors & Ergonomics Society (HFES)

The Human Factors and Ergonomics Society (HFES) is the only organization in the United States dedicated specifically to the human factors profession. The HFES was formed in 1957 and typically maintains about 5,000 members. For more information, visit their website at www.hfes.org.

International Ergonomics Association (IEA)

The International Ergonomics Association (IEA) is a federation of over 40 ergonomics and human factors societies located all over the world. All members of the HFES are automatically also members of the IEA. The main contact point within the IEA is through the office of their Secretary General. For more information, visit their website at iea.cc.

Figure . A list of maintenance-related incidents/accidents and their causes.